The Bambu Lab AMS (Automatic Material System) is one of the most powerful upgrades available for multi-color and multi-material printing. Whether you're using it with the X1 Carbon, P1S Combo, or A1 Combo (AMS Lite), it offers unmatched convenience — but only when used with compatible filaments and spools.

In this guide, we’ll walk you through everything you need to know to get the best performance from your AMS, including supported filament types, spool requirements, and troubleshooting tips.

🎯 What is the AMS?

The Automatic Material System is an enclosed, humidity-controlled filament feeder that allows you to print with up to 4 different filaments — or even 16 with multiple AMS units daisy-chained.

Features:

-

Automatic filament switching

-

Filament runout and tangle detection

-

RFID auto-detection (with Bambu Lab spools)

-

Supports PLA, PETG, ABS, TPU, PA, and more (with limitations)

✅ Filaments Compatible with AMS

While the AMS is technically open to third-party filaments, some materials and spool formats perform better than others.

👍 Best Performing Materials:

| Material |

Works with AMS? |

Notes |

| PLA |

✅ Excellent |

Low-friction, ideal for multi-color prints |

| PETG |

✅ Good |

Slightly more abrasive; keep AMS clean |

| TPU (Soft/Flexible) |

⚠️ Limited |

Needs to be stiff enough; some 95A works |

| ABS / ASA |

✅ With enclosure |

Needs temp stability |

| PA / Nylon |

✅ Dry only |

Must be kept dry; AMS helps with that |

| Carbon-Fiber Reinforced |

⚠️ Depends |

Higher wear on feed system; use sparingly |

📦 Spool Compatibility: What Fits in the AMS?

AMS units are physically limited by spool size and shape. Non-standard spools may cause feeding issues or not fit at all.

✔️ Recommended Spool Specs:

If your filament doesn’t come on a compatible spool, you can:

-

Rewind it onto a reusable Bambu Lab spool

-

Use refillable spools that support RFID tags

-

Manually load it without the AMS (for tricky materials)

🧵 Using Third-Party Filament with AMS

You can successfully use third-party filaments in the AMS system, provided they meet the spool size requirements and feed smoothly. For best results, we recommend:

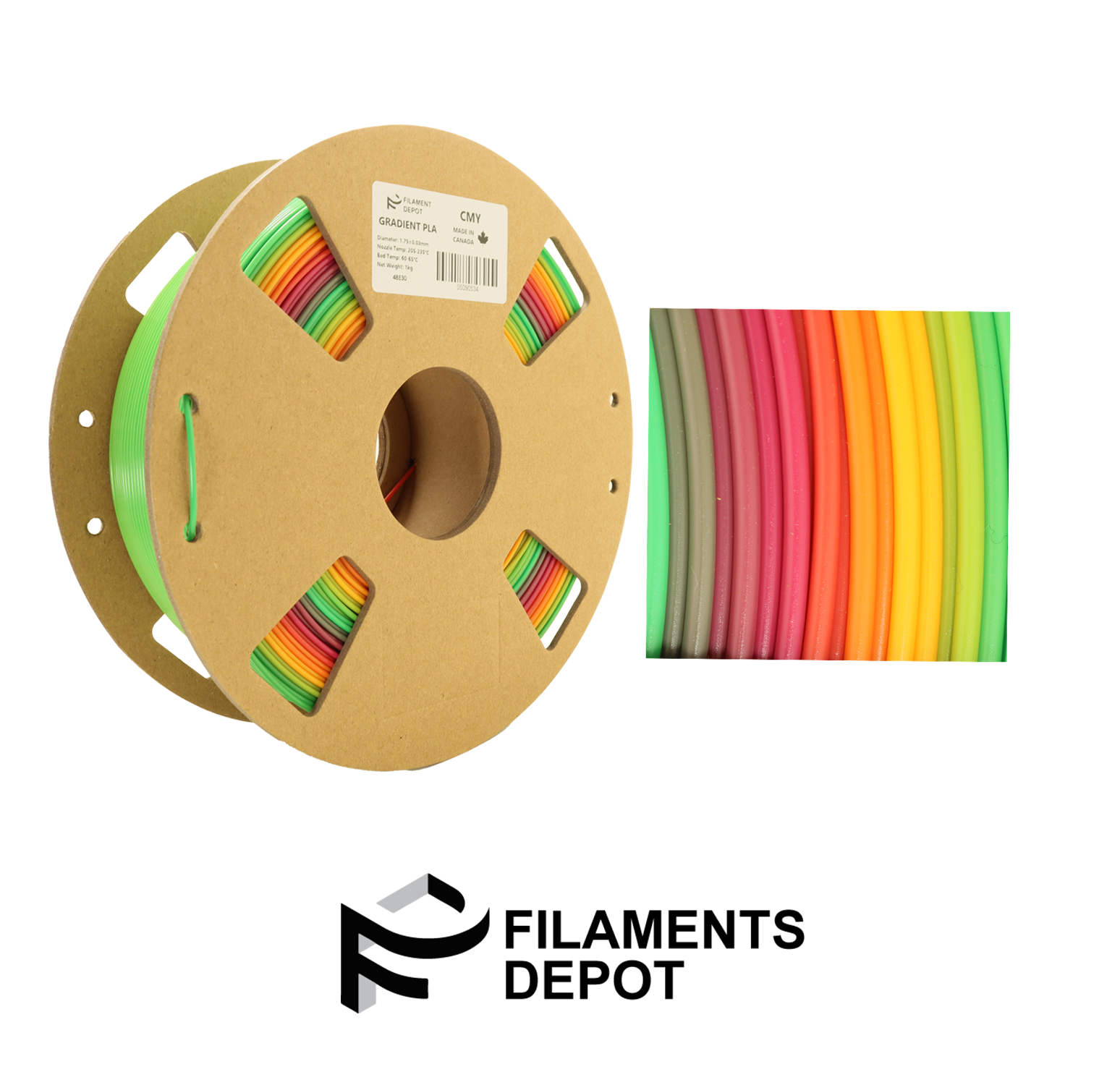

![]()

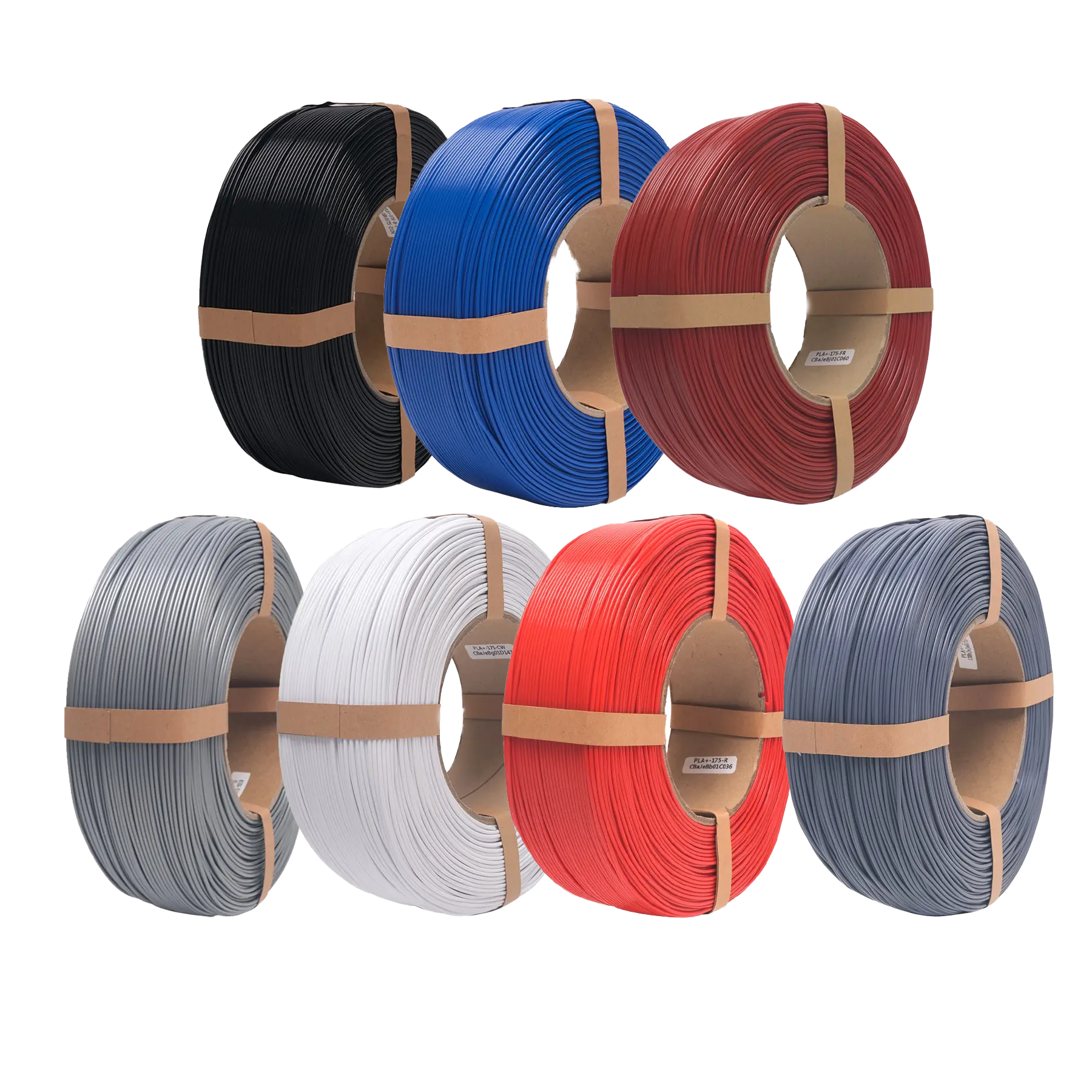

![]()

Both are AMS-compatible and have been tested for excellent print performance using our custom configuration profiles available for Bambu Studio.

📥 Download AMS Profiles:

👉 Click here to download the configuration file

🛠️ Tips for Smooth AMS Operation

-

Keep filament dry

AMS includes humidity control, but hygroscopic filaments (like Nylon) should be used quickly or stored in dry boxes.

-

Avoid sticky or soft filament

Very flexible filaments may not feed properly due to AMS’s long PTFE paths and drive system. Use direct-drive loading when needed.

-

Label third-party filaments manually

If using non-Bambu filament, enter the type, color, and temperature manually via Bambu Studio for accurate print profiles.

-

Clean AMS periodically

Dust or filament debris inside can affect feeding. Open the lid and wipe down rollers and guides occasionally.

📌 Troubleshooting Common AMS Issues

| Problem |

Solution |

| Filament won't load |

Check for tangles, dry box compatibility, or spool size |

| Material jams mid-print |

Use a separator (glue stick) for sticky materials like PETG |

| Wrong filament selected |

Reassign manually in Bambu Studio |

| TPU keeps failing |

Try direct loading without AMS for flexible filaments |

🛒 Final Thoughts

The AMS is an outstanding upgrade that saves time, enables colorful prints, and adds a layer of automation that 3D printing has long needed. With the right filaments and setup, it's an absolute powerhouse for hobbyists and professionals alike.

Looking for AMS-compatible accessories, spools, or upgrade kits? Explore them at DigitMakers.ca — your source for Bambu Lab printers, parts, and supplies in Canada.