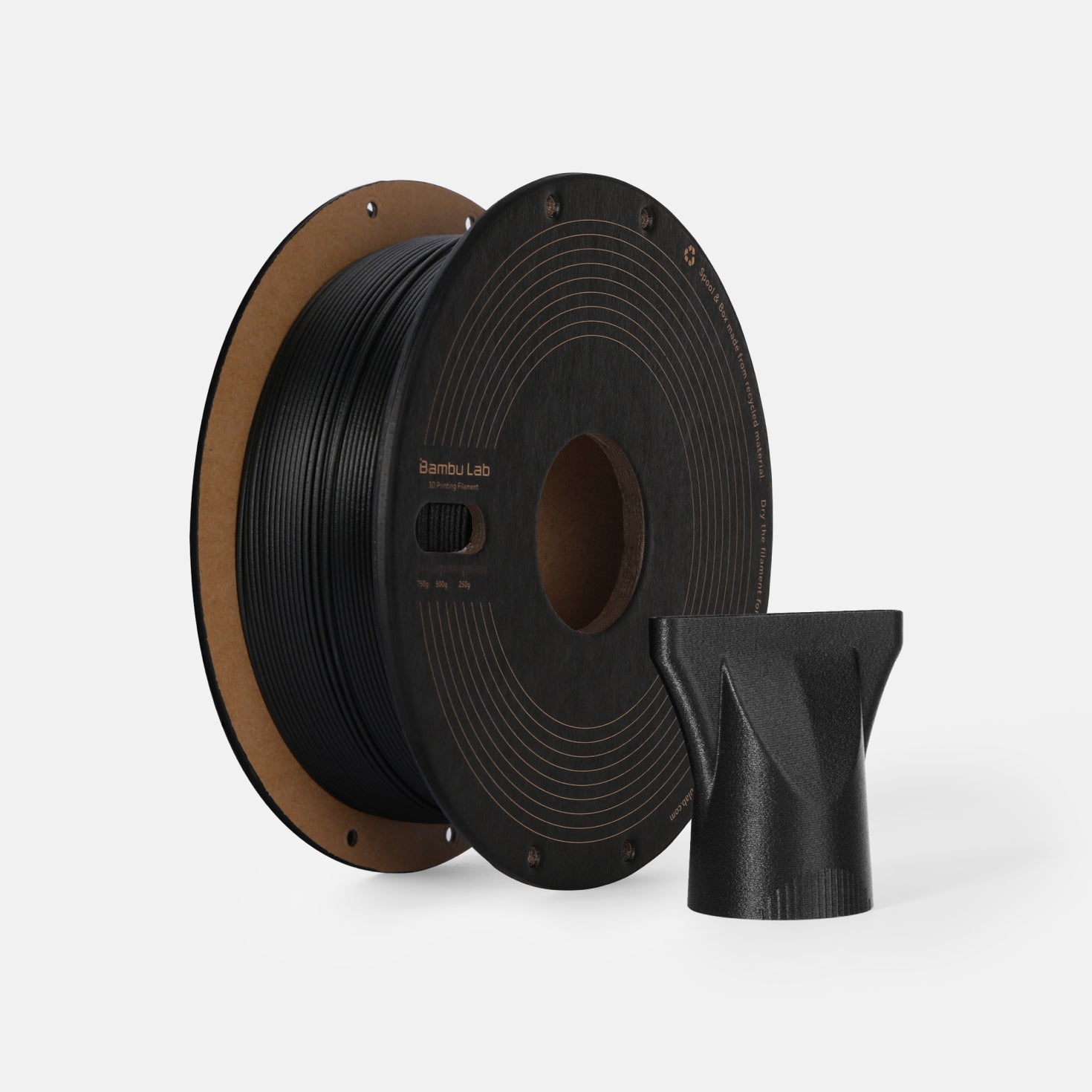

Bambu PPA-CF

Bambu PPA-CF, a premium fiber-reinforced nylon, delivers industrial-grade printing quality with precise 1:1 reproduction. Renowned for its exceptional mechanical properties and reliable performance in humid or high-temperature environments, Bambu PPA-CF is ideal for engineering applications, from mechanical prototypes to automotive components. Additionally, its broad printer compatibility sets a new standard for professional engineering filaments. Experience the power of Bambu PPA-CF and bring your designs to life!

Product Features

- Metal-Like Strength

- Industrial-Grade Precision

- Stable Performance in Humid Conditions

- Unmatched Performance Under High Temperatures

- Compatible with a Wide Range of Printers

- Diameter: 1.75mm +/- 0.05mm

Cautions for Use

- 0.2 mm Nozzle Not Compatible

- Hardened Steel Nozzle Mandatory

- AMS & AMS lite Not Compatible

- Must Be Dried before Use to Achieve Optimal Print Quality

Metal-Like Strength

PPA-CF offers strength approaching metal levels, being 48% stronger and 102% stiffer than normal PA6-CF. This filament excels in mechanical properties, making it ideal for high-performance engineering applications. Perfect for repairs, it can effectively replace automotive and industrial parts with exceptional durability and reliability.

| Filament |

Normal PA6-CF |

Bambu PA6-CF |

Bambu PAHT-CF |

Bambu PPA-CF |

| Stiffness (Bending Modulus - XY, Dry State) |

4870 MPa |

5460 MPa |

4230 MPa |

9860 MPa |

| Strength (Bending Strength - XY, Dry State) |

141 MPa |

151 MPa |

125 MPa |

208 MPa |

Industrial-Grade Precision

Achieve industrial-grade precision with Bambu PPA-CF. Its superior dimensional stability ensures that your high-precision prototypes match your design drawings exactly, without warping or deformation. Rely on PPA-CF for the accuracy you need in every project.

Stable Performance in Humid Conditions

Bambu PPA-CF supports long-term, stable use in humid environments, even underwater. With a moisture absorption rate 66% lower than normal PA6-CF, it maintains its stiffness and thermal properties over time. Whether printing propellers, customizing surfboards, or any other water-resistant application, PPA-CF delivers reliable performance.

Unmatched Performance Under High Temperatures

Bambu PPA-CF boasts unmatched heat resistance, capable of withstanding prolonged exposure to temperatures up to 227°C without compromising its structural integrity or performance. This filament remains reliable and robust in extreme environments, making it perfect for industrial, mechanical, or automotive parts that must tolerate ultra-high temperatures.

Compatible with a Wide Range of Printers

Bambu PPA-CF is compatible with P1S, X1C, and X1E printers, requiring only an enclosure and a hardened steel nozzle. This filament is easier to use than you might think, printing smoothly at nozzle temperatures between 280°C and 310°C. Expand your possibilities with Bambu PPA-CF.

Accessory Compatibility

|

Recommended |

Not Recommended |

| Build Plate |

Smooth PEI Plate / Textured PEI Plate |

/ |

| Hotend |

Hardened Steel 0.4mm / 0.6mm (recommended) / 0.8 mm |

Hotend with Stainless Steel Nozzle (all size)

Hotend with Hardened Steel Nozzle (0.2 mm) |

| Glue |

Bambu Glue Stick |

Bambu Liquid Glue |

Recommended Print Settings

| Drying Settings (Blast Drying Oven) |

100 - 140°C, 8 - 12 h |

| Printing and Keeping Container's Humidity |

< 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature |

280 - 310 °C |

| Bed Temperature (with Glue) |

100 - 120 °C |

| Printing Speed |

< 100 mm/s |

Physical Properties

| Density |

1.25 g/cm³ |

| Vicat Softening Temperature |

232 °C |

| Heat Deflection Temperature |

227 °C |

| Melting Temperature |

258 °C |

| Melt Index |

8.4 ± 0.7 g/10 min |

Mechanical Properties

| Tensile Strength |

168 ± 4 MPa |

| Breaking Elongation Rate |

3.2 ± 0.4 % |

| Bending Modulus |

9860 ± 480 MPa |

| Bending Strength |

208 ± 6 MPa |

| Impact Strength |

41.7 ± 2.8 k |

Downloads

Printing Tips

Printing Tips

Drying Recommendations:

In a blast drying oven: 100°C to 140°C for 8 to 12 hours.

On an X1 printer's heatbed: 110°C to 120°C for 10 to 12 hours (less effective than a blast drying oven).

-

Important Note: Higher temperatures within the drying range yield better results, but do not exceed 160°C to avoid damaging the spool.

Storage Tips:

-

Storage Condition: To prevent the filament from absorbing moisture, use an airtight storage container with desiccant during printing.