Panda Buildplate

Elevate your 3D printing experience with the BIQU Panda BuildPlate CryoGrip Pro, designed for Bambu X1, P1, A1, and A1 Mini printers. This premium double-sided build plate features a 7-layer composite structure, high magnetic spring steel, and low-energy printing compatibility for effortless adhesion and removal. Achieve precision and durability with every print!

CryoGrip Pro Frosbite

| Feature |

Frostbite |

Glacier |

| Model |

Frostbite |

Glacier |

| Surface Finishes |

Rough Texture, Better Grip |

Smooth Texture |

|

G.S.I. (Grip Strength Index)* |

10 |

8 |

| Cold Print Material Compatibility |

Compatible only with PLA and PETG, offering extremely good cold printing adhesion. |

Excels with most engineering materials, with good cold printing adhesion, but not as good as Frostbite with PLA and PETG. |

| Temperature Ranges |

PLA: 30-50°C PETG: 50-70°C |

PLA: 45-55°C PETG: 60-75°C |

| Engineering Material Compatibility |

Not compatible with materials besides PLA & PETG. |

Compatible with all materials with nozzle temperatures below 300°C |

| Use Case Scenario Recommendations |

- Dedicated plate to print PLA & PETG only |

- Excels at engineering materials like PA.

- Print PLA, PETG, ABS, PA, and other engineering materials.

- All-rounder plate for different filament exploration.

- Significantly more adhesion than PEI but slightly less than Frostbite with PLA and PETG.

- May require brim for some parts. |

| Other Features |

AR Code printed |

AR Code sticker

Heat-isolating handle |

| Cleaning Methods |

Water and Soap Only |

Water and Soap

Alcohol |

*G.S.I. refers to the Material Compatibility Chart for more details.

Revolutionary 7 layer Design Achieve Superior Print Stability

| Layer |

Description |

| 1. Base Plate |

580HV Hardness, highly ferromagnetic spring steel with strong magnetic holding to physically constrain your print from warping. No more worrying about the edge of the build plate lifting during large prints. |

| 2. Base Coat |

Ultra-strong bonding agent ensures excellent adhesion between the top coat and spring steel, with zero risk of peeling even after repeated bending. |

| 3. Intermediate Coating |

Impact-resistant, corrosion-resistant, and long-lasting with no risk of damage from nozzle probing. |

| 4. Top Coat |

Porous Oleophobic Polymer Coating - Attracts filament at the molecular level for ultra-strong adhesion, eliminating print failures due to detachment. Achieve 100% adhesion without heating, using half the energy.

- Self-Cleaning Property - Reduces the negative impact of accidental fingerprints on adhesion performance. |

Unmatched, Adhesion, Zero Heat

CryoGrip Pro Frostbite delivers unparalleled adhesion for PLA, PETG at room temperature, reducing warping of large prints and remaining scratch and wear-resistant over long periods of time.

Cool and Clog Free

Uniquely designed to print for PLA at low temperature the CryoGrip Pro Frostbite prevents your filament from softening and slipping in the extruder due to high chamber temperature.

Effortless Print Removal Bend and Pop!

The CryoGrip Pro Series provides excellent adhesion while still allowing print to be easily removed by bending the plate. For larger or more intricate print use scraper to gently lift the edges, then pry them off carefully. if a print sticks too firmly, place the plate in a freezer for 10 minutes to assist with removal.

![]()

![]()

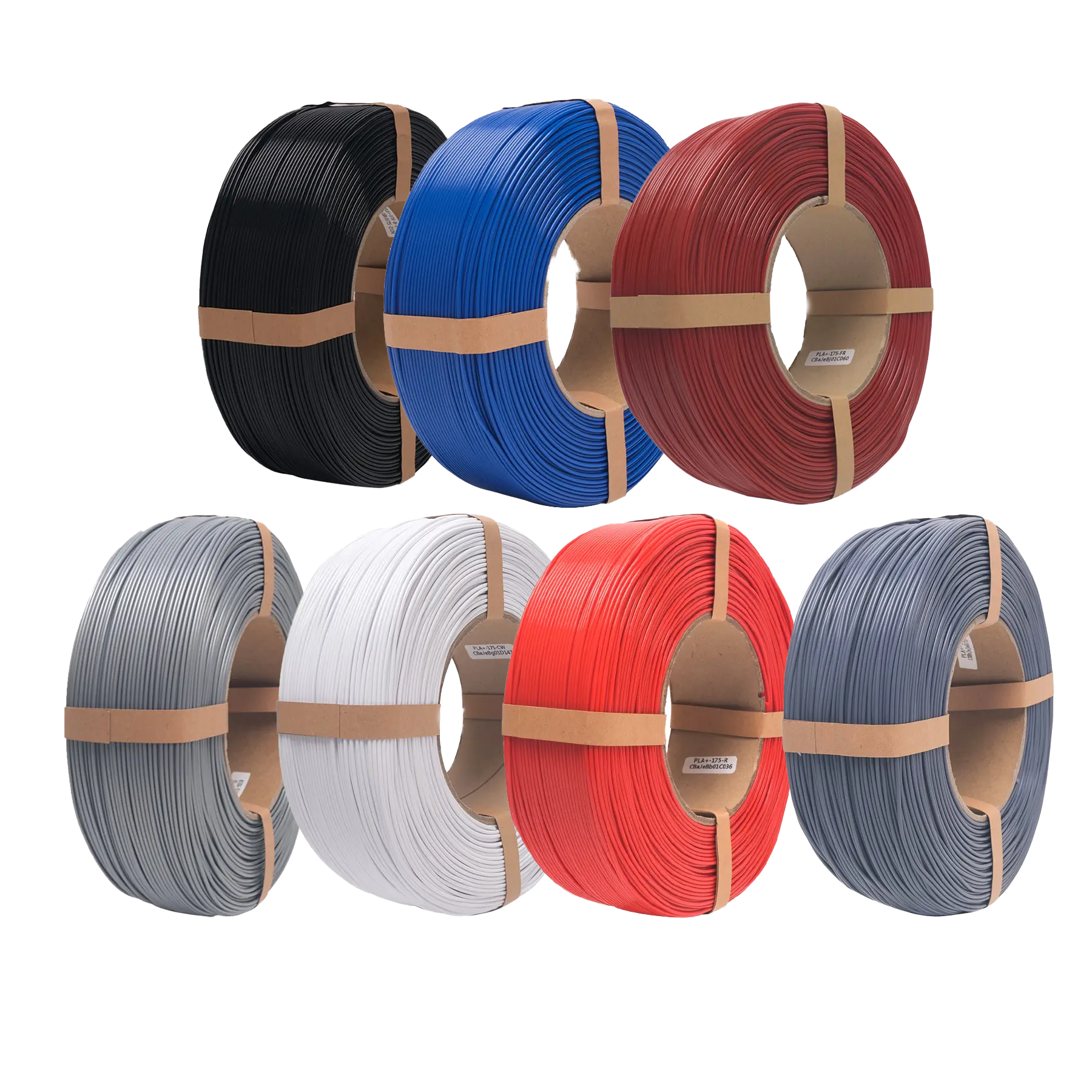

Filament Compatibility Chart

| Filament Type |

Standard |

Pro Frostbite |

Pro Glacier |

| PLA/CF |

HT: 30-50°C |

HT: 30-50°C |

HT: 45-55°C |

|

GSI: 9 |

GSI: 10 |

GSI: 8 |

|

AAR: NAR |

AAR: NAR |

AAR: NAR |

| PLA HR |

HT: NC |

HT: NC |

HT: FMRT |

|

GSI: NC |

GSI: NC |

GSI: 10 |

|

AAR: NC |

AAR: NC |

AAR: NAR |

| PETG/CF |

HT: 50-70°C |

HT: 50-70°C |

HT: 55-75°C |

|

GSI: 9 |

GSI: 10 |

GSI: 8 |

|

AAR: NAR |

AAR: NAR |

AAR: NAR |

| ABS/CF |

HT: NC |

HT: NC |

HT: FMRT |

|

GSI: NC |

GSI: NC |

GSI: 8 |

|

AAR: NC |

AAR: NC |

AAR: NAR |

| TPU |

HT: NC |

HT: NC |

HT: FMRT |

|

GSI: NC |

GSI: NC |

GSI: 10 |

|

AAR: NC |

AAR: NC |

AAR: NAR |

| PVA |

HT: NC |

HT: NC |

HT: FMRT |

|

GSI: NC |

GSI: NC |

GSI: 8 |

|

AAR: NC |

AAR: NC |

AAR: NAR |

| Nylon/CF |

HT: NC |

HT: NC |

HT: FMRT |

|

GSI: NC |

GSI: NC |

GSI: 9 |

|

AAR: |

AAR: |

AAR: NAR |

| AOF < 300°C |

HT: NC |

HT: NC |

HT: FMRT |

| (Any other filament) |

GSI: NC |

GSI: NC |

GSI: 6 |

|

AAR: NC |

AAR: NC |

AAR: MRA |

| AOF > 300°C |

HT: NC |

HT: NC |

HT: AFMRT |

| (Any other filament) |

GSI: NC |

GSI: NC |

GSI: 5 |

|

AAR: NC |

AAR: NC |

AAR: AR |

| Cleaning Solution Tolerance Water |

Water + Soap only |

Water + Soap only |

Water + Soap + Alcohol |

Abbreviation Explanation (Each filament has 3 criteria):

-

HT - Heatbed Temperature (Centigrade)

-

FMRT: Filament Manufacturer Recommended Heatbed Temperature

-

AFMRT: May require temperatures Above Filament Manufacturer Recommended Heatbed Temperature

-

NC: Not Compatible

-

GSI - Grip Strength Index (Rated from worst to best on a scale from 1-10)

- 1-6: Moderate adhesion (Highly recommended to use brim.)

- 7-8: Good adhesion (Brim not needed. If the print only lifts in odd corners, use mouse ear pads on those corners.)

- 9-10: Excellent adhesion (Do not use brim unless your part is extremely small or prone to warping.)

-

AAR - Adhesion Aid Recommendation

-

NAR: No Adhesive Required

-

MRA: May Require Adhesive depending on filament

-

AR: Adhesive Recommended