If you’ve been printing engineering materials, composites, or high-volume functional parts on your Bambu Lab printer, you know that your choice of nozzle matters. The right nozzle not only affects surface quality and precision — it determines how well your setup handles abrasive and demanding filaments.

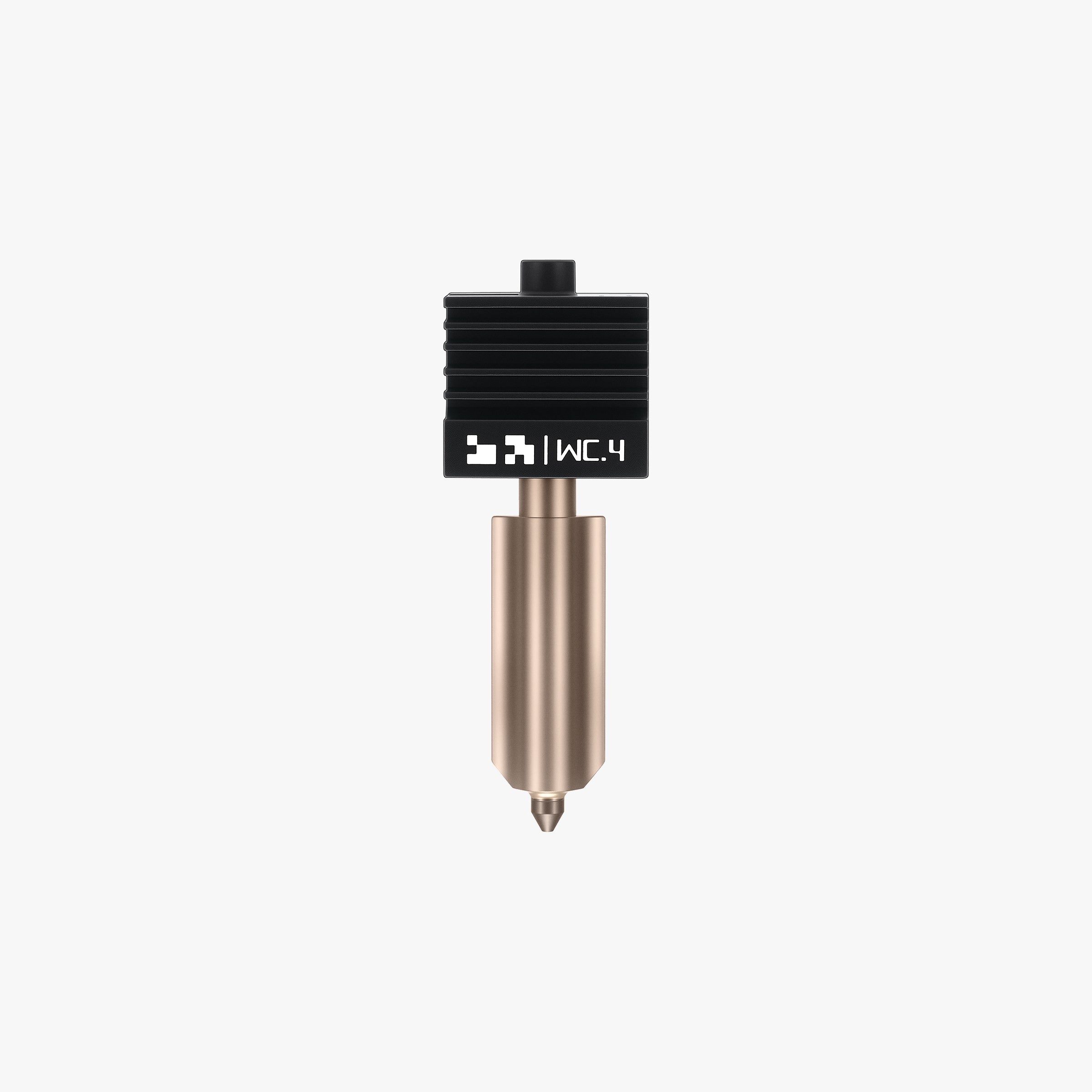

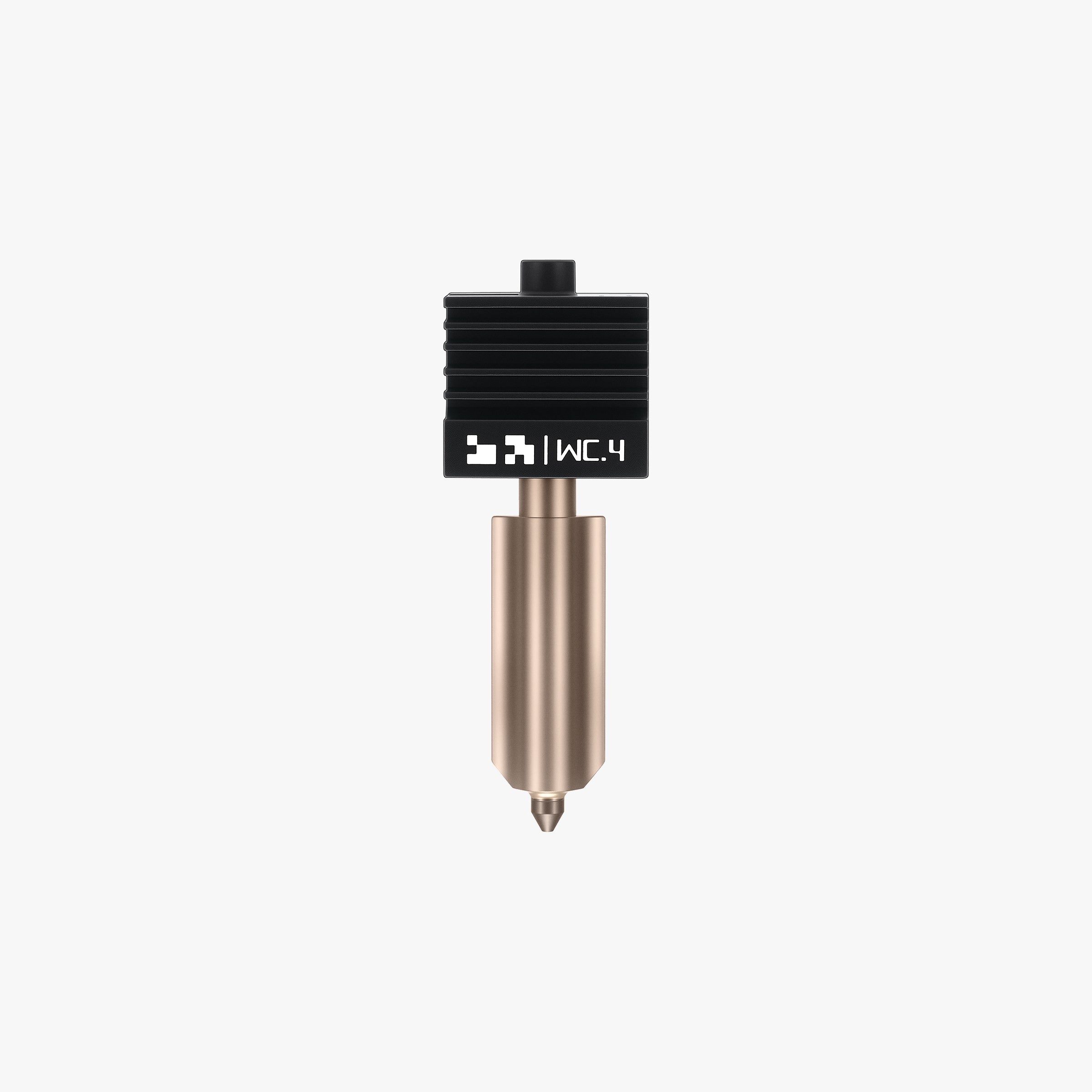

Enter the Bambu Lab Tungsten Carbide Nozzle (for H2 / P2S). Built for strength, durability, and consistency, this nozzle is a step up from hardened steel — and in this guide, we’ll explain exactly why it’s worth the upgrade.

Traditional brass nozzles are easy to print with and excellent for everyday materials like PLA or PETG. But once you start working with abrasive filaments — such as:

…you quickly discover that brass and even some hardened steel nozzles wear out quickly. This leads to:

✔ Consistent under-extrusion

✔ Poor dimensional accuracy

✔ Surface artifacts

✔ Frequent replacements

A tungsten carbide nozzle solves these problems because tungsten carbide is much harder and more abrasion-resistant than steel or brass. It simply doesn’t wear down as fast.

1. Long-Lasting Wear Resistance

Tungsten carbide rates significantly higher on the hardness scale than brass or standard hardened steel — which means:

-

You print hundreds of hours without degradation

-

Dimensional accuracy stays consistent

-

Nozzle geometry doesn’t deform over time

This is especially useful if you print lots of carbon fiber, glass fiber, or metal-filled filaments, which chew up lesser nozzle materials.

2. Better Filament Flow Consistency

Abrasion isn’t the only challenge — abrasive fillers tend to roughen the inner bore of brass nozzles, leading to:

A tungsten carbide nozzle maintains a smooth, consistent bore throughout its lifespan, helping your printer push filament cleanly and predictably.

3. Stronger Hotend Performance with Demanding Materials

If you’re printing:

…the tungsten carbide nozzle ensures your hotend is not the weak link in the printing chain. Less wear = fewer failed prints = faster prototyping and production.

4. Supports High Volumetric Flow Rates

When paired with the Bambu Lab H2 Series or P2S (especially with high-flow extruders), tungsten carbide nozzles let you push filament faster without sacrificing quality.

This matters when:

✔ Printing large parts

✔ Using high-infill functional prints

✔ Working on prototypes or tight deadlines

You get speed and strength without needing to upgrade your entire hotend or printer.

🔍 Tungsten Carbide vs Hardened Steel — What’s the Real Difference?

| Feature |

Hardened Steel Nozzle |

Tungsten Carbide Nozzle |

| Hardness |

High |

Very High |

| Abrasion Resistance |

Moderate |

Excellent |

| Ideal for CF/Glass/Metal Filaments |

Yes |

Yes — longer life |

| Lifespan |

Good |

Superior / Longest |

| Cost |

Lower |

Higher (but better ROI) |

| Flow Consistency Over Time |

Degrades |

Stable |

In short: hardened steel is great. But tungsten carbide lasts significantly longer under abrasive use, which translates to less downtime and fewer nozzle changes.

Here are printing scenarios where this upgrade makes the most sense:

🎯 Functional Parts

Print strong mechanical parts with minimal wear on your hotend, even after dozens of prints.

🛠 Carbon Fiber & Glass Fiber Filaments

The abrasive nature of fiber fillers is where tungsten carbide shows its biggest advantage.

🚗 Engineering Prototypes

Gears, fixtures, housings, and load-bearing parts printed with reinforced filaments benefit from consistent extrusion.

🦾 High-Volume Printing

If your workflow involves long or repeated prints, this nozzle greatly reduces consumable costs and wear-related failures.

📈 Practical Tips for Using the Tungsten Carbide Nozzle

🔧 Install & Tighten Properly

Always follow manufacturer torque guidelines. A properly tightened tungsten carbide nozzle ensures:

✔ No leakage

✔ Optimal thermal transfer

✔ Better first layers

Note: Avoid overtightening — tungsten carbide can be brittle if mis-handled.

🔄 Pair With a Hardened Heatbreak

While tungsten carbide resists abrasion in the nozzle, using a hardened steel heatbreak keeps filament feed consistent upstream.

🧼 Keep Filaments Dry

Even the best nozzle can’t fix moisture-laden filament. Use:

✔ AMS / AMS HT dry boxes

✔ Filament drying before printing

✔ Dry storage between sessions

This improves layer adhesion and overall strength.

🛠 Consider Nozzle Size Based on Your Goals

-

0.4 mm: Great all-around performance

-

0.6 mm / 0.8 mm: Higher flow and faster large prints

-

Smaller nozzles (0.2–0.3 mm): More detail but slower pace

Tungsten carbide performs across all sizes — just choose based on your print’s requirements.

💡 Is It Worth the Upgrade?

Short answer:

Yes — especially if you print abrasive or engineering filaments regularly.

Here’s why:

✔ Less frequent nozzle replacement

✔ Better long-term dimensional accuracy

✔ Higher flow consistency

✔ Holds up to demanding print jobs

✔ Reduces downtime and filament waste

For makers, professionals, and engineers who print functional parts or composites, the tungsten carbide nozzle turns your H2 or P2S into a more reliable, future-proof machine.

🏁 Final Thoughts

The Bambu Lab Tungsten Carbide Nozzle isn’t just a luxury — it’s one of the best practical upgrades you can make for consistent, abrasion-resistant printing.

Whether you’re tackling:

This nozzle gives you greater reliability and longer service life, making it a smart investment for years of heavy use.