FibreX™ PP+GF30 - 1.75mm 500g Black

Related Products

xTool S1 Enclosed Diode Laser Cutter - UL and ETL Certified

xTool S1 Enclosed Diode Laser Cutter - UL and ETL Certified

$2,599.00

Best Value Bundle In the Market This is an all-in-one, ultra-precision laser engraver. From beginner to expert, there's something for everyone. Plus, with 4 switchable laser modules, you can upgrade at any time to excel in any scenario. What's Included: xTool S1 40W Basic Kit xTool S1 40W Honeycomb Panel: Never compromise to oi...

Prusa XL Textured Powder-coated Steel Sheet

$130.00

OVERVIEW: The heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. Powder coating directly on metal makes it very hard to damage this build plate. If a heated nozzle crashed into it, the metal can dissipate the heat. Powder coating also gives the surface a distinct textured loo...

Original Prusa XL Enclosure

Original Prusa XL Enclosure

$1,399.00

Original Prusa XL Enclosure: Modular box for your XL 3D printer Seamless Integration The XL Enclosure is designed for seamless integration with the rest of the printer. Not just the physical parts, but also the software: because the Enclosure is directly connected to the mainboard of the printer, you can configure a number of useful functions ...

Original Prusa XL 3D Printer - ETL Certified

Original Prusa XL 3D Printer - ETL Certified

$6,999.00

The Original Prusa XL is the most innovative 3D printer on the market, offering possibilities that no single-nozzle multi-material printer can replicate. With a state-of-the-art five-head tool changer, top print quality, extreme precision, huge print volume, and zero-waste printing, the Original Prusa XL establishes a new category for itself. Fe...

eSUN ABS-GF - 1.75mm 1kg - Various Colors

$39.99

Adding glass fiber reinforced materials to ABS and modifying, it strengthens the rigidity and toughness of ABS, it has excellent impact resistance and chemical corrosion resistance, and has good performance in scenes with high strength requirements such as some tooling and fixtures; Features Matte Texture Wear Resistance Chemical Resistanc...

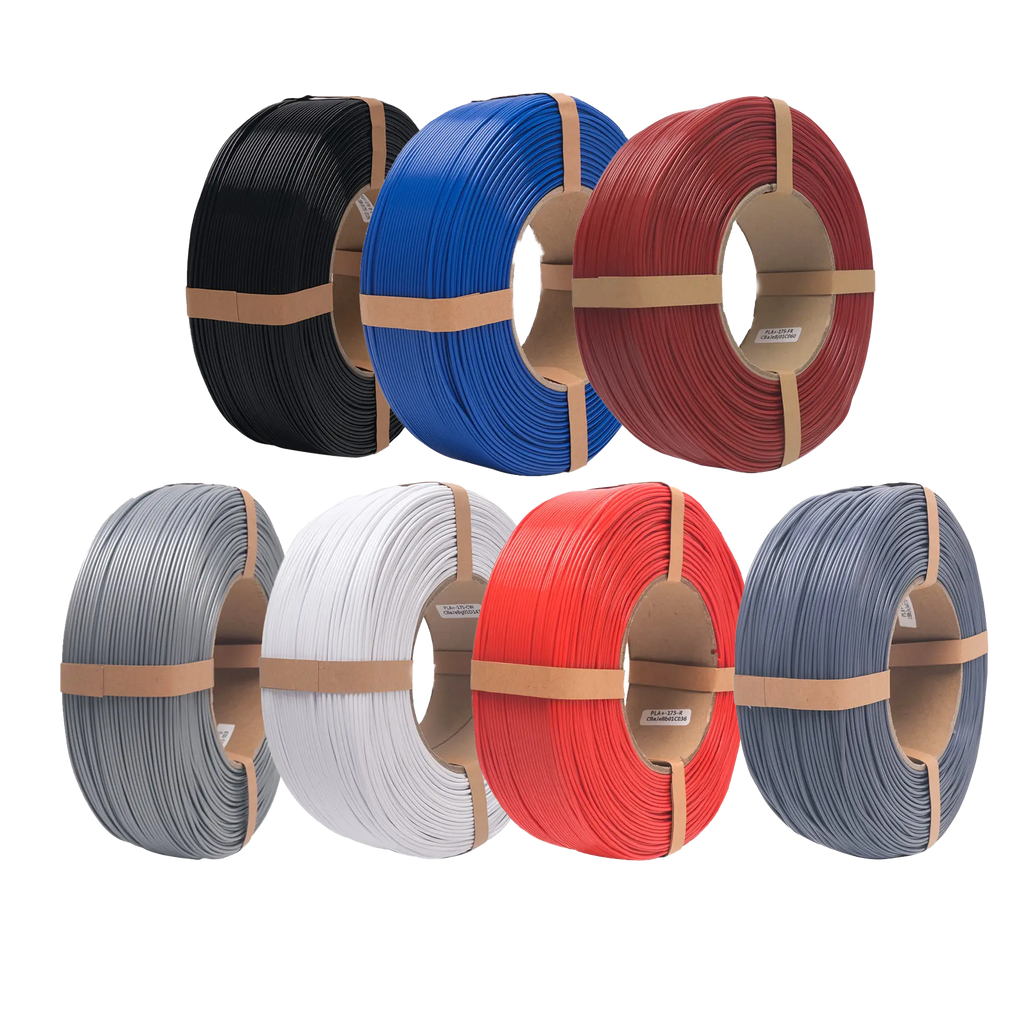

eSUN PLA+ Bambu Lab Compatible Refill 1.75 mm 1kg

$24.99

Please note that this is not compatible with the older version of the eSun eSpool. Kindly click here for eSun eSpool+ Bambu Lab Compatible Refilament is an innovative packaging form for 3D printing materials. Unlike traditional designs, it neatly coils the filament into a compact shape, eliminating the need for plastic or cardboard spools. Ref...

eSUN PETG Bambu Lab Compatible Refill 1.75 mm 1kg

$24.99

PETG filament is a high cost performance 3D Printer material with water resistance, chemical resistance and high toughness. COMPATIBLE WITH ESUN ESPOOL+ Description PETG material is tougher than ABS; The product printed with petg filament has translucent and smooth surface. It's easy to print like PLA without temperature chambe...

eSun eSpool+ Bambu Lab Compatible

$6.99

A reusable and detachable eSpool+ specially designed for Refilament. eSpool+ is made of sturdy ABS material, can observe the usage of filament in real time. FAQ Questions Possible reason Solution The latch structure is difficult to insert Mess up with front and back side The concave side is the front side, and the smooth side is the back...

eSUN PLA+ CMYK - 1kg 1.75mm

eSUN PLA+ CMYK - 1kg 1.75mm

$79.99

The four CMYK PLA+ sets contain cyan, magenta, yellow and white PLA+ filaments. Based on the principle of color mixing, through the superposition of these four colors, explore and create infinite colors, bringing a rich visual experience to 3D printing works.

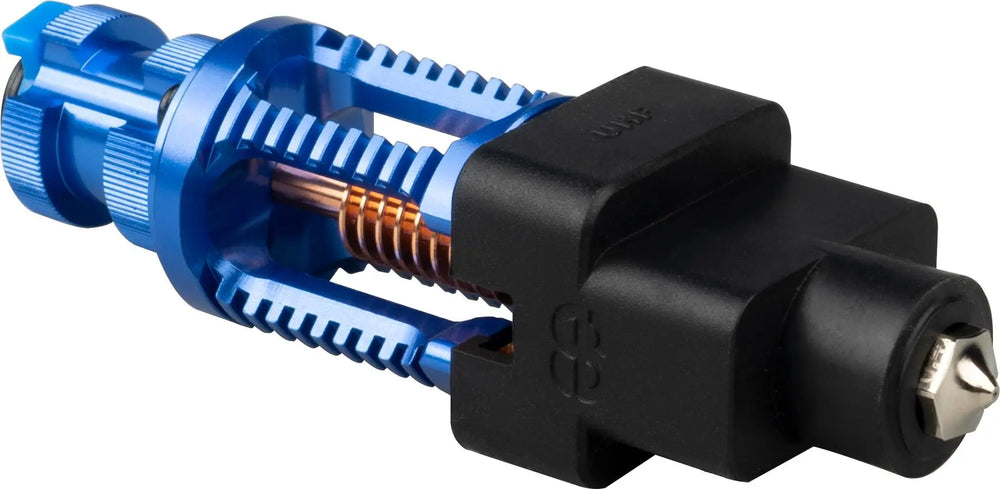

Phaetus Rapido 2 Hotend HF - Blue

$127.99

Phaetus Rapido 2 Hotend Ultra-high flow printing up to 36mm³/s High-efficiency ceramic, reaching 220°C in just 60 seconds Detachable 104NT thermistor One-handed nozzle changing Product Name: Rapido 2 Size: 22.3 x 22.3 x 79.2 mm Material Selection: Aluminum Heatsink, great heat dissipation; Titanium Heatbreak, exce...

Phaetus Dragon Hotend - Ultra High Flow - Blue

$121.99

Phaetus Dragon Ultra High Flow Hotend Ultra-high-speed printing The extended copper-alloy heater block is matched with an extended nut that allows for ultra-high extrusion throughput of up to 70.5 mm³/s. Ultra-thin titanium alloy heatbreak A thin-walled heatbreak with only 0.25 mm wall thickness and high wear resistance ensures exc...

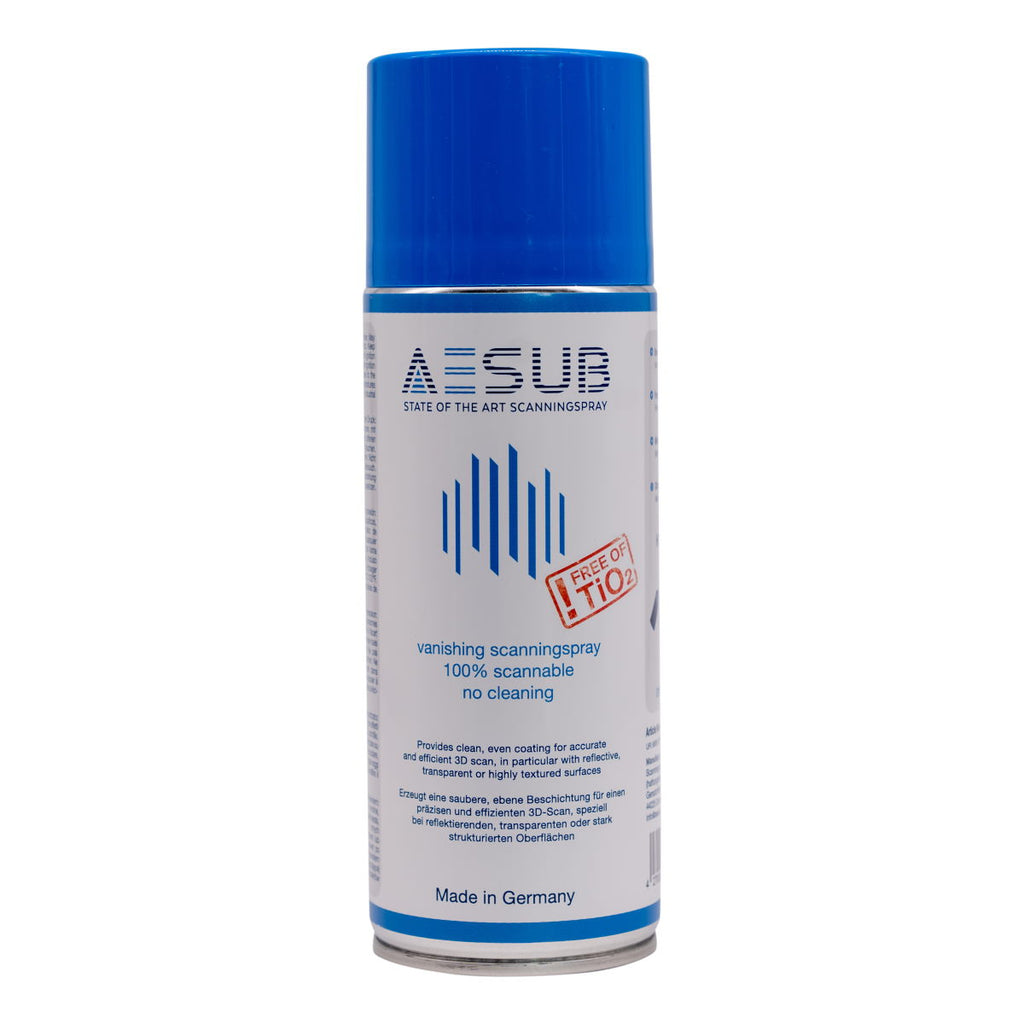

AESUB Blue - Vanishing Spray for 3D Scanning 400ml

AESUB Blue - Vanishing Spray for 3D Scanning 400ml

$44.50

AESUB blue Disappearing state-of-the-art scanning spray No cleaning required Thin and homogeneous coating Free of pigments Developed and approved by scanning experts AESUB blue is a self-vanishing scanning spray developed by scanning experts. The spray evaporates within a few hours, meaning that there is no need for cleaning after scanning. ...