Element HT Base is currently in stock.

Element HT8 and HT Pro are preorder ONLY

Contact sales@digitmakers.ca for lead time & more info

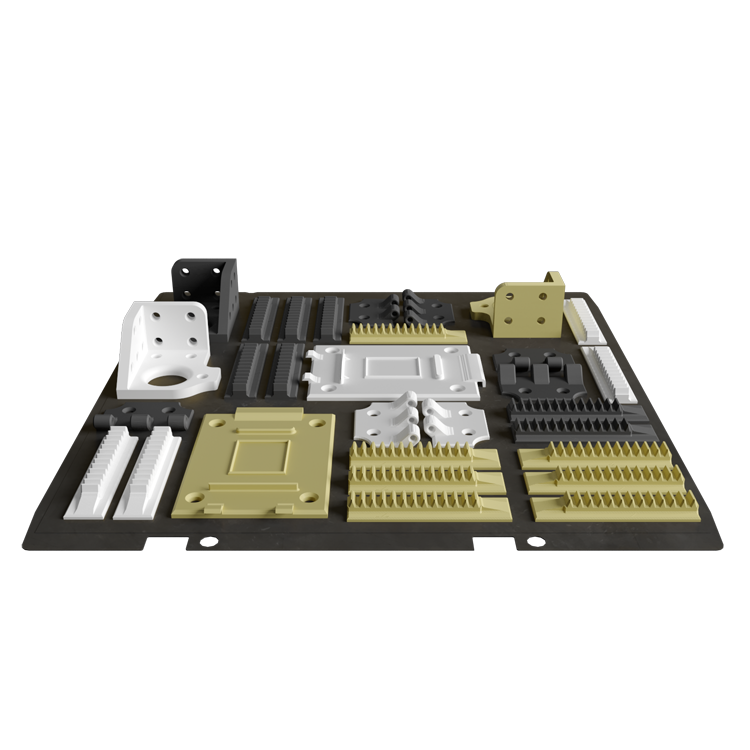

ELEMENT HT from Mosaic Manufacturing

FLEXIBLE, INDUSTRIAL & POWERFUL

THE NEXT GENERATION OF INDUSTRIAL DESKTOP 3D PRINTING

Element HT includes all the benefits of Element but with the additional capability of printing high temperature engineering materials.

The major innovation of automating your workflow further improves on HT’s efficiency. By using Mosaic Material Pods and Materials you will be able to print complex high temperature models with unrivaled simplicity.

Features and benefits of Element HT include:

- 500°C hot-end, 120°C heated bed, 80°C heated chamber

- Integrated Palette X, allowing up to 8 materials/colours in a single print

- Modular toolhead, kinematically coupled

- Integrated purge container with densifier

- Cloud connected to Canvas slicer software

- LED print status indicator incorporated into design

- 2-year manufacturer’s warranty

- HIWIN Linear Rails

- CoreXY Kinematics Systems

- Trinamic Stepper Drivers

ACCESS THE FULL MOSAIC MATERIAL CATALOGUE

Element HT works best when paired with Mosaic Materials and Pods, and is able to print every material Mosaic currently offers, including:

- Nylon & CF Nylon

- ABS

- PLA

- PETG

- TPU

- PVA

- HIPS

- PEEK

- PEKK

- Ultem 9085

MULTI-MATERIAL MANAGEMENT & AUTOMATED WORKFLOW EXPLAINED

As mentioned above, using Mosaic Materials and Material Pods with Element HT allows you to automate your workflow.

Each Material Pod contains a motor which feeds filament from the Pod to Palette X, and onwards to the print head. Unlike our standalone Palette device, Palette X does not splice the materials. The reason for this is that when using, for example, combinations of high temperature with support materials, splicing becomes less reliable. Element, along with Palette X, has full control over material management and therefore does not require splicing. This promotes higher quality prints while also resulting in less material waste.

Element is also cloud connected to CANVAS. This means creating, editing, organizing and slicing your multi-material models and sending them to the printer is extremely easy. What could once take up to an hour or more becomes a process reduced to a matter of minutes.

Features Highlight

WITH A BUILD VOLUME OF 14” ^3, YOU’RE ABLE TO MAXIMIZE PRODUCTIVITY AND PRINT SEVERAL PIECES AT ONCE, IN DIFFERENT COLOURS AND MATERIALS.

ELEMENT OPTIMIZES THE PRINTING PROCESS BY SIMULTANEOUSLY PRINTING SUPPORTS WHILE COMPLETING YOUR PART(S) IN ANY NUMBER OF MATERIALS.

ELEMENT HT’S ACTIVELY HEATED CHAMBER WILL REACH 90°C AND WILL AID IN THE PROCESS OF PRINTING MATERIALS LIKE PEEK, PEKK AND ULTEM 9085.

A MODULAR DESIGN MAKES IT EASIER THAN EVER TO REMOVE YOUR PRINT HEAD FOR REPAIRS OR A SWAP, AND REINSTALLING IT IS JUST AS SIMPLE!

CLOUD CONNECTED TO CANVAS, FREE SINGLE USER LICENSE INCLUDED

CANVAS is Mosaic’s simple and easy-to-use slicer software. CANVAS comes free for a single user and CANVAS TEAMS will be available for those with a larger workforce, allowing effective collaboration.

- Perfect for one material, built for multi-material.

- Set accesses for everyone on the team, from Owners to Contributors.

- Apply color, logos, serial numbers and more directly to your single file 3D models by digitally painting in CANVAS.

- Share, Save, organize, and track your print settings in the cloud for yourself or with the team.

- Monitor your prints from home, or anywhere, using Element’s webcams connected to CANVAS.

How Does It Work?

-

Choose: Element uses a modular direct-drive toolhead, capable of 350°C material prints, which can be removed in seconds. Choose up to 8 materials/colours per print with a single toolhead. Element HT broadens your selection to include engineering grade materials with a hot-end capable of 500°C.

-

Slice: Create prints that are up to 14” 3 and use CANVAS to easily paint or assign up to 8 materials/colours per print. Upload files wirelessly and control your printer from anywhere where an internet connection is available using a web browser to access canvas3d.io. Spend less time configuring settings by using premade print profiles tuned for Mosaic materials.

-

Load: Start your print and Mosaic Material Pods work directly with Palette X to seamlessly automate the filament loading process. It is worth noting that this process is only automated when using Mosaic Materials.*

-

Print: Watch your print complete using CoreXY kinematics, Trinamic stepper drivers and rapid travel speeds on HIWIN linear rails. Transition quickly between materials without losing build space with Element’s short material path coupled with our transition densifier system, which deposits transition material safely into a removable container. While Element works, use the touchscreen UI to check printer operation at any time directly from the printer.

-

Monitor: Element’s built in webcam lets you check on your print remotely through CANVAS to make sure the process is running smoothly. Mosaic Materials contain RFID technology that enables automated failure and filament run-out detection. You will be notified by the LED status indicator and on the touchscreen UI on the front of Element if the printer or print requires an operator’s attention.

-

Completion & Removal: Mosaic’s build plates are magnetically held in place so they are easy to remove from Element. They are also flexible which makes removing the print from the plate a painless process. Upon placing the plate back into Element to start your next print, it will automatically level to achieve consistent first layers.