|

|

|

Fused Deposition Modeling

|

|

|

|

| Body³ |

|

| Build Volume (W*D*H) |

Single Nozzle Printing: 325*320*325 mm³

|

Dual Nozzle Printing: 300*320*325 mm³

|

|

Total Volume for Two Nozzles: 350*320*325 mm³

|

|

| Chassis |

|

| Outer Frame |

|

|

|

|

| Physical Dimensions |

|

| Net Weight |

31 kg |

| Toolhead |

|

| Hotend |

All Metal |

| Extruder Gear |

Hardened Steel |

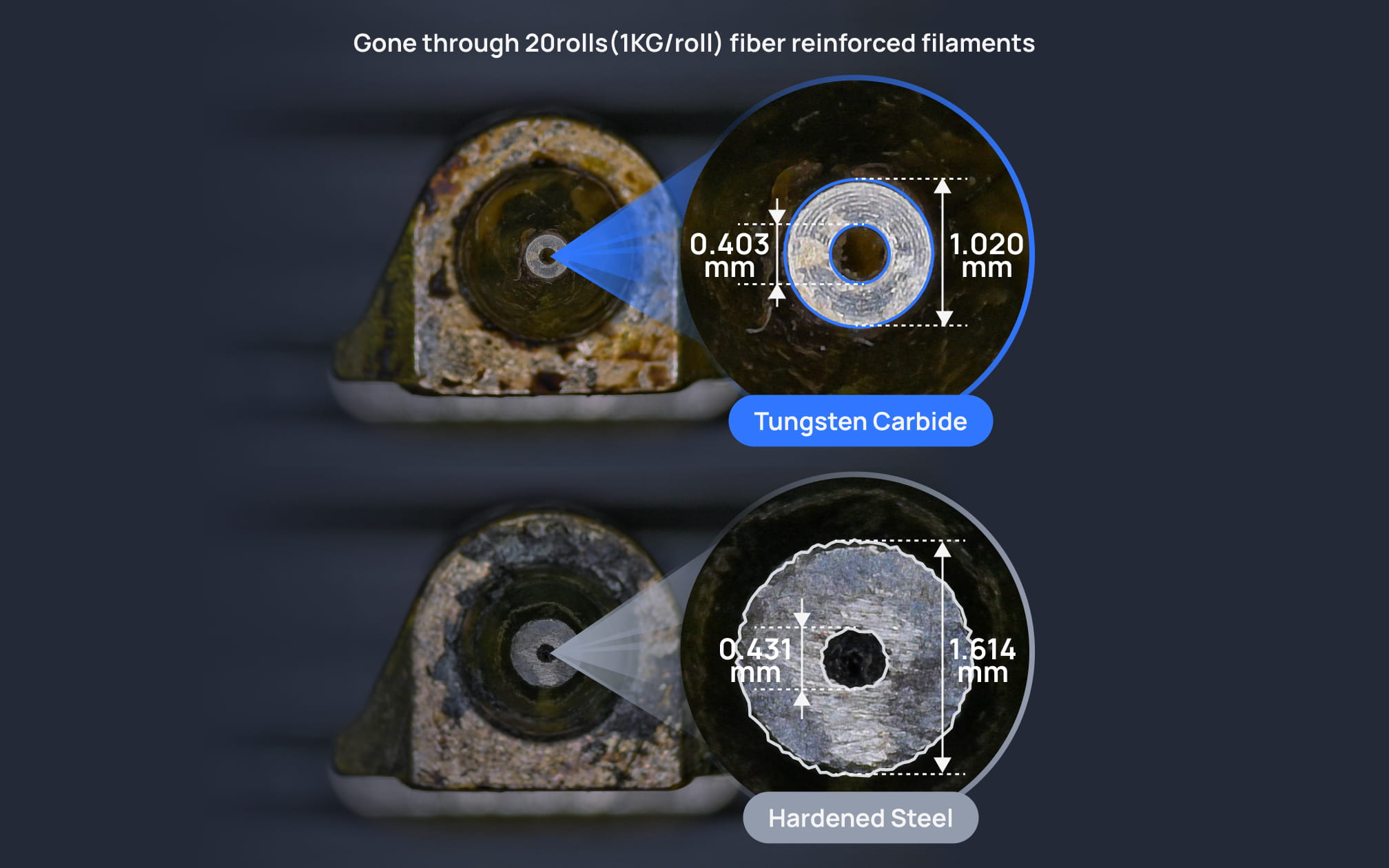

| Nozzle |

|

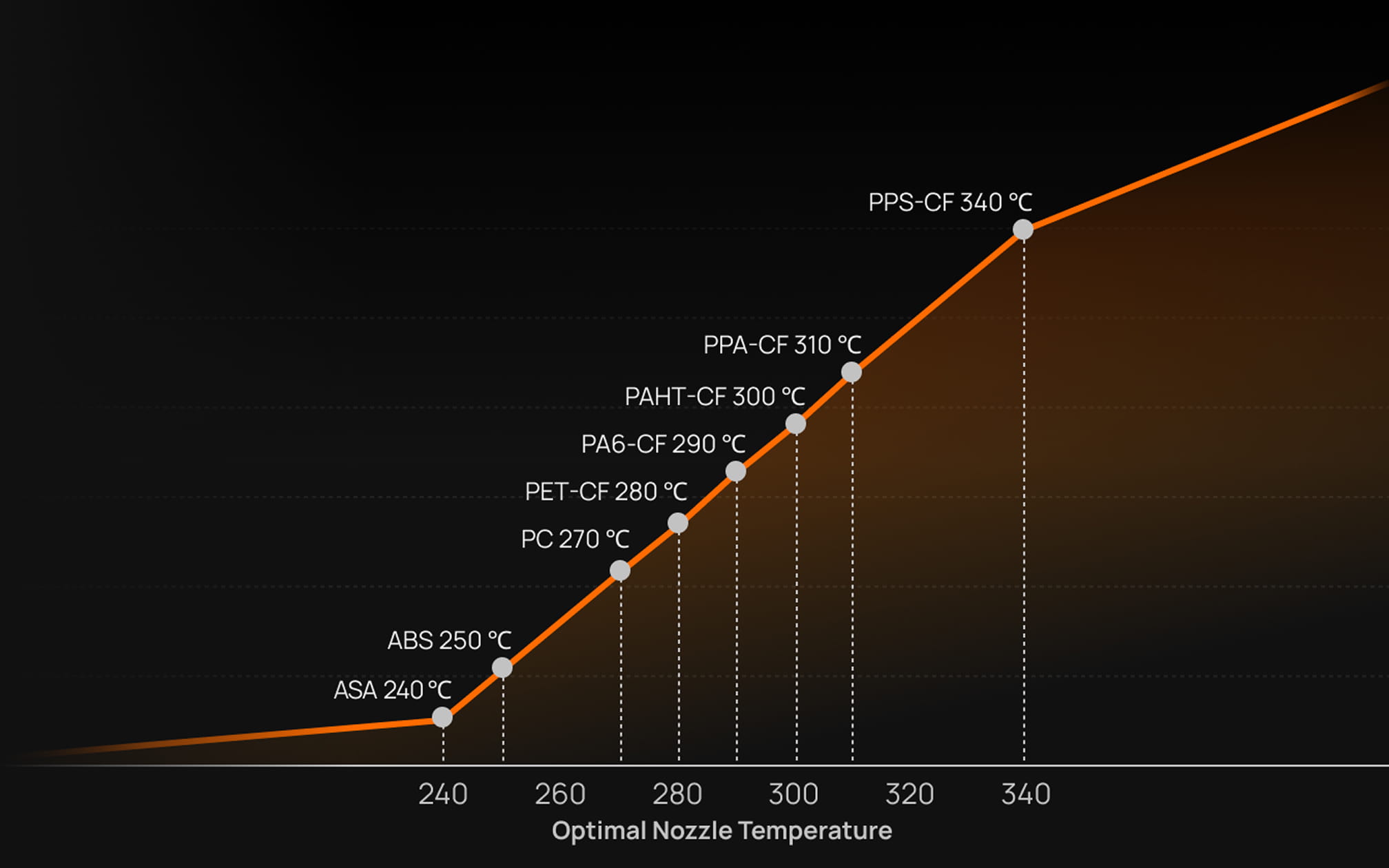

| Max Nozzle Temperature |

350 ℃ |

| Included Nozzle Diameter |

0.4 mm |

| Supported Nozzle Diameter |

0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

|

| Filament Cutter |

Built-in |

| Filament Diameter |

1.75 mm |

| Extruder Motor |

Bambu Lab High-precision Permanent Magnet Synchronous Motor

|

| Heatbed |

|

| Build Plate Material |

|

| Included Build Plate Type |

|

| Supported Build Plate Type |

Textured PEI plate, Smooth PEI Plate

|

| Max Heatbed Temperature |

120 ℃ |

| Speed |

|

| Max Speed of Toolhead |

1000 mm/s |

| Max Acceleration of Toolhead |

20,000 mm/s² |

| Max Flow for Hotend |

40 mm³/s |

(Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 ℃ printing temperature)

|

|

Chamber Temperature Control

|

|

| Active Chamber Heating |

Supported |

| Max Temperature |

65 ℃ |

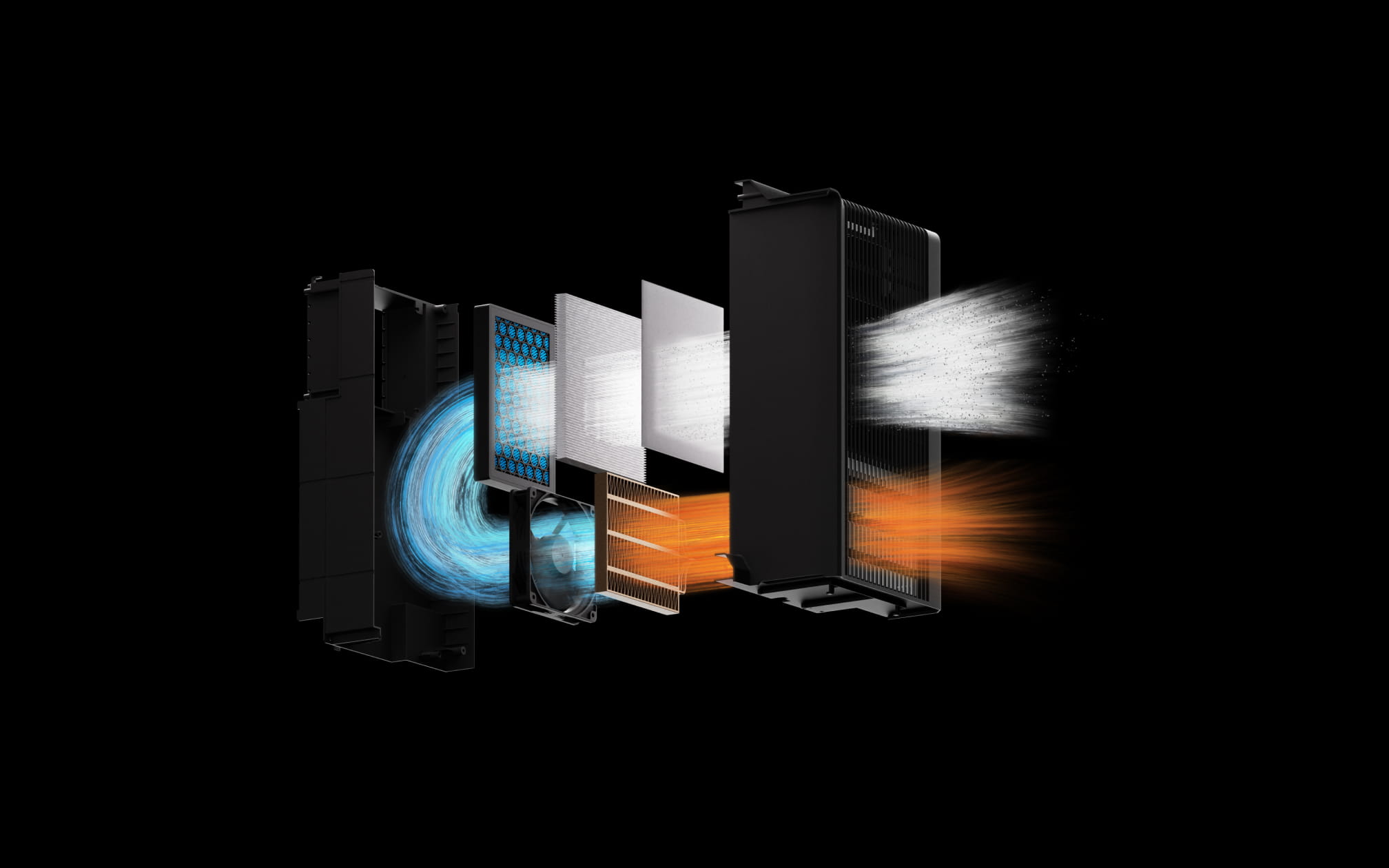

| Air Purification |

|

| Pre-filter Grade |

G3 |

| HEPA Filter Grade |

H12 |

| Activated Carbon Filter Type |

|

| VOC Filtration |

Superior |

| Particulate Matter Filtration |

Supported |

| Cooling |

|

| Part Cooling Fan |

|

| Cooling Fan for Hotend |

|

| Main Control Board Fan |

|

| Chamber Exhaust Fan |

|

| Chamber Heat Circulation Fan |

|

| Auxiliary Part Cooling Fan |

|

| Toolhead Enhanced Cooling Fan |

|

|

|

|

| PLA, PETG, TPU, PVA, BVOH |

Optimal |

| ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA |

Superior |

| PPA-CF/GF, PPS, PPS-CF/GF |

Ideal |

| Sensor |

|

| Live View Camera |

|

| Nozzle Camera |

|

| Toolhead Camera |

|

| Door Sensor |

Supported |

| Filament Run Out Sensor |

Supported |

| Filament Tangle Sensor |

Supported |

| Filament Odometry |

|

| Power Loss Recovery |

Supported |

|

|

|

| Voltage |

100–120 VAC / 200–240 VAC, 50/60 Hz

|

| Max Power1 |

|

2200 W@220 V / 1320 W@110 V

|

|

|

|

Please purchase the version corresponding to your region's voltage.

|

|

|

|

|

|

|

| 10 ℃-30 ℃ |

|

|

|

| Electronics |

|

| Touchscreen |

5-inch 720*1280 Touchscreen

|

| Storage |

Built-in 32 GB EMMC and USB Port

|

| Control Interface |

Touchscreen, mobile App, PC App

|

| Motion Controller |

Dual-core Cortex-M4 and Single-core Cortex-M7

|

| Application Processor |

|

| Neural Processing Unit |

2 TOPS |

| Software |

|

| Slicer |

Bambu Studio |

Supports third-party slicers which export standard G-code, such as Super Slicer, PrusaSlicer and Cura, but certain advanced features may not be supported.

|

|

| Supported Operating System |

|

| Network Control |

|

| Ethernet |

Available |

| Wireless Network |

Wi-Fi |

| Network Kill Switch |

|

| Removable Network Module |

Available |

| 802.1X Network Access Control |

Available |

| Wi-Fi |

|

| Operating Frequency |

2412–2472 MHz, 5150–5850 MHz (FCC/CE)

|

2400–2483.5 MHz, 5150–5850 MHz (SRRC)

|

|

| Wi-Fi Transmitter Power (EIRP) |

2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC)

|

5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC)

|

|

5 GHz Band3: <30 dBm (CE); <24 dBm (FCC)

|

|

5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE)

|

|

| Wi-Fi Protocol |

|

| Ethernet |

|

| Port Type |

RJ45 |

| Speed |

|

| AMS 2 Pro |

|

| Dimensions |

|

| Net Weight |

2.5 kg |

| Housing Material |

ABS/PC |

| Filament Supported |

PLA, PETG, ABS, ASA, PET, PA, PC, PVA (dried), BVOH (dried), PP, POM, HIPS, Bambu PLA-CF/PAHT-CF/PETG-CF/Support for PLA/PETG, and TPU for AMS

|

| Filament Not Supported |

TPE, generic TPU, PVA (damp), BVOH (damp), Bambu PET-CF/TPU 95A, and other filament that contains carbon fiber or glass fiber

|

| Filament Diameter |

1.75 mm |

| Spool Dimension |

|

|

|

|

| RFID Identification |

Supported |

| Highest Temperature |

65 ℃ |

| Filament Supported2 |

PLA, PETG, Support for PLA/PETG, ABS*, ASA*, PET*, PA*, PC*, PVA*, BVOH *, PP, POM*, HIPS*, Bambu PLA-CF*/ PAHT-CF*/ PETG-CF*, and TPU for AMS*

|

| Active Moisture Discharge |

Supported |

| Sealed Storage |

Supported |

| Temperature and Humidity Detection and Maintenance |

Supported. Real-time temperature and humidity can be displayed on the screen3, Bambu Studio, and Bambu Handy.

|

| Input |

24 V 4 A |

| AMS HT |

|

| Dimensions |

|

| Net Weight |

1.21 kg |

| Housing Material |

PC/PA |

| Flame Retardant Grade |

UL 94 V-0 |

| Screen |

Supports displaying real-time temperature and humidity, and remaining drying duration.

|

| Filament Supported |

Feeder Unit Filament Inlet: PLA, PETG, ABS, ASA, PET, PA, PC, PVA (dried), BVOH (dried), PP, POM, HIPS, Bambu PLA-CF/PAHT-CF/PETG-CF/Support for PLA/PETG, and TPU for AMS

|

Bypass Filament Outlet: TPE, generic TPU, Bambu PET-CF/TPU 95A, and other filament that contains carbon fiber or glass fiber

|

|

| Filament Not Supported |

|

| Filament Diameter |

1.75 mm |

| Spool Dimension |

|

|

|

|

| RFID Identification |

Supported |

| Filament Odometry |

Supported |

| Maximum Temperature |

85 ℃ |

| Filament Supported |

PLA, PETG, Support for PLA/PETG, ABS, ASA, PET, PA, PC, PVA, BVOH, PP, POM, HIPS, Bambu PLA-CF/ PAHT-CF/ PETG-CF, and TPU for AMS

|

| Active Moisture Discharge |

Supported |

| Rotating Drying Mode |

Supported |

| Sealed Storage |

Supported |

| Top Lid Open Detection |

Supported |

| Temperature, Humidity Detection and Maintenance |

Supported. Real-time information can be displayed on the printer screen3, AMS HT screen, Bambu Studio, and Bambu Handy.

|

| Voltage |

DC: 24 V |

AC: 100 V–240 V~, 50 Hz/60 Hz

|

|

| Average Power |

150 W |